As an analyst, you strive for accurate and reproducible results when running methods and analysis, wanting to see good peak shape, resolution and separation.

However, we know over time, chromatography equipment and instrumentation will wear, and parts will eventually break. To take steps to prevent this, you need to ensure that scheduled regular cleaning and servicing of your high-performance liquid chromatography (HPLC) equipment is in place.

Below, we’ve shared some quick tips and good lab practices for cleaning your HPLC and columns, that you can begin incorporating into your lab’s cleaning or maintenance rota.

These tips are just guidelines, and if there is something specific that your system needs, please get in touch to speak with our friendly team.

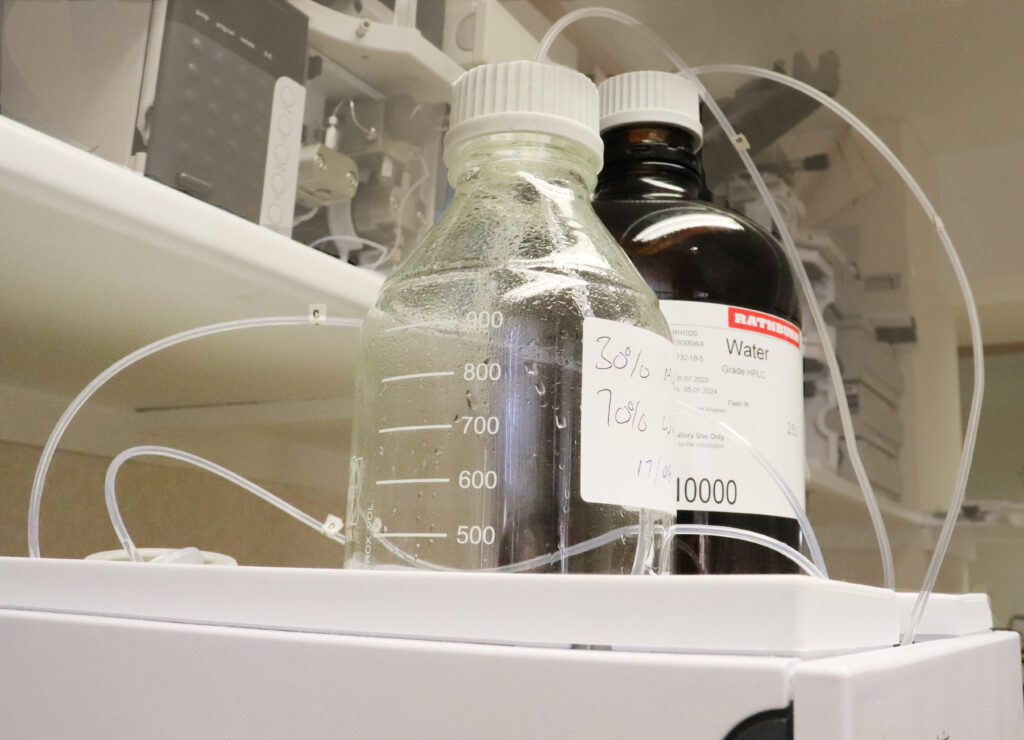

To ensure accurate results and prevent potential complications, you should use only the highest-quality solvents when conducting chromatography. HPLC-grade solvents are the best option, as they are free of impurities and contaminants that could cause false peaks or blockages in the equipment.

If you use water-based solvents or mobile phases, these should be changed daily to minimise potential algal growth and precipitation of salts, which can block the degasser or solvent filters.

When using solvents, you should always:

If installed on your system, a HPLC pump “seal wash” function is strongly recommended when using water or water-based solvents, like salt buffers.

This function helps to increase the performance and lifetime of the piston seal, while also being beneficial for removing unwanted deposits which can be left behind on the pistons and the seals.

Combining this with daily flushing of the HPLC system prevents build-up and reduces the maintenance needed. We recommend that any seal wash solution (50:50 methanol/water or 10:90 isopropanol/water) is changed regularly, i.e., weekly, to reduce contamination.

To further clean the system, and in a worst-case scenario, 6N nitric acid can be used to flush through the system.

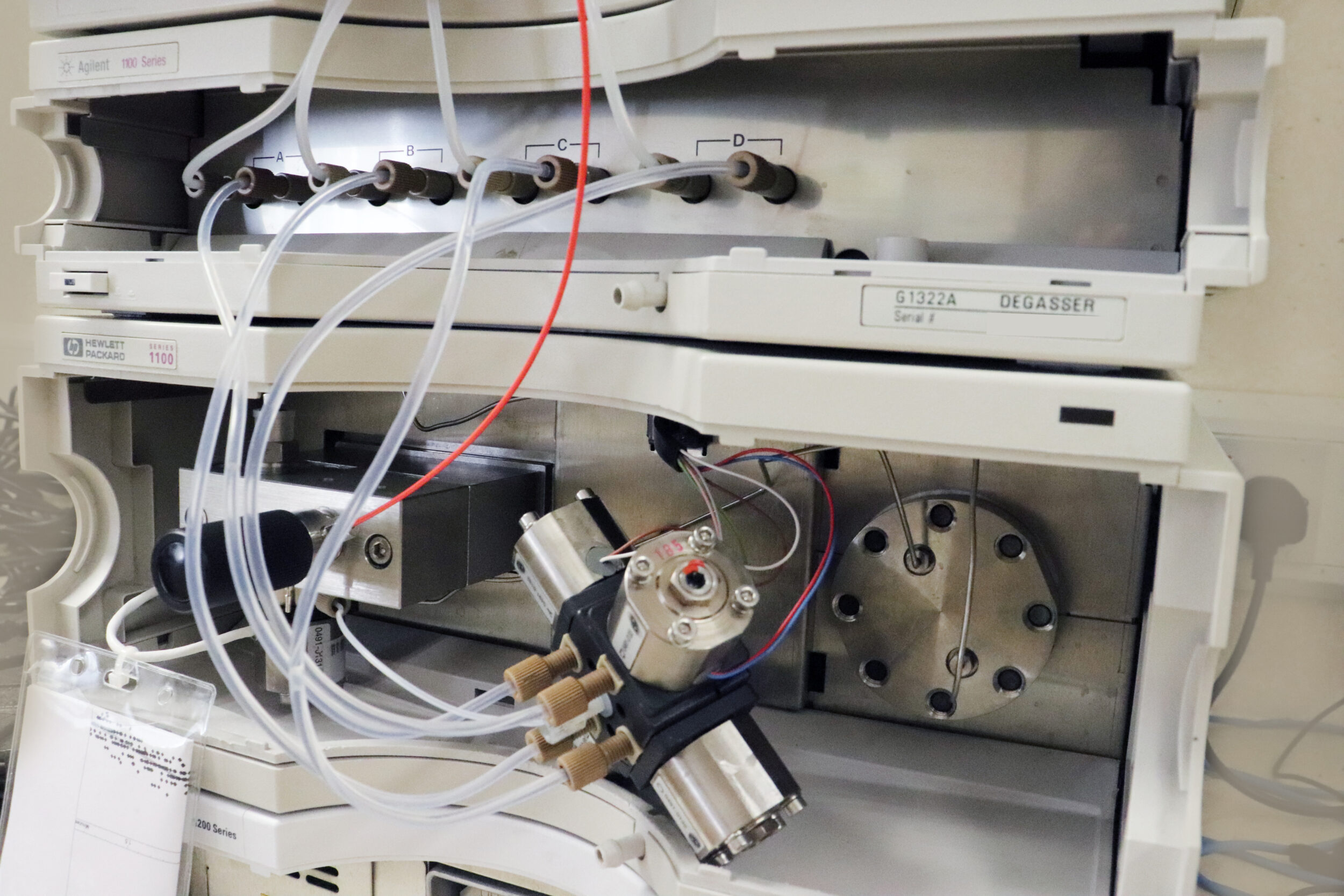

As they’re critical components, it’s essential to regularly clean and maintain your degassers, pumps, and detector. Below, we’ve included some tips on cleaning these components.

When using solvents with degassers, pumps and detectors, always check the compatibility of buffers and organic solvents and avoid allowing the system to dry out.

What to do if your system dries out

If solvents are incompatible, precipitation can form, causing blockages and issues in the degasser chamber or the pump’s MCGV (multi-channel gradient valve), both of which can affect the flow path and influence results. To counteract this, you should:

In general, selecting a wash solution is based on what you use in your system.

The wash solution must be fully soluble with all the samples being injected and any buffer solutions you use. It’s wise to always keep an organic content in your wash solution to inhibit algae growth and other undesirable bugs.

Due to these criteria, it is possible to use one or more wash solutions depending on your needs.

For example, in many situations, a basic wash solution of 50:50 Water/Methanol can be used, but again this will be down to your own requirements, so always check first.

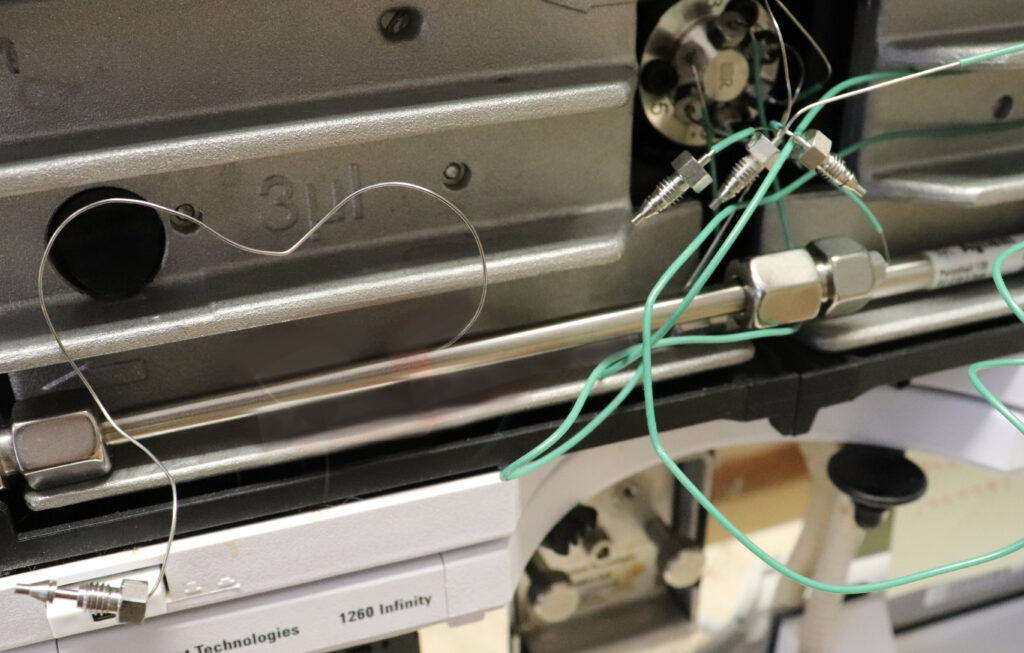

For optimal HPLC column care, you should always read the storage and cleaning information on the guidance manual usually shipped with the column.

However, if this isn’t available for a deep clean, it is possible to reverse flush the column into a beaker and flush it out at a lower flow rate for around 20-30 column volumes.

It is good practice in a lab environment where multiple analyses and methods are run on the same system to have a column logbook detailing:

Always ensure you use suitable fittings with your columns – different types of HPLC columns may require different fitting dimensions. Using one that doesn’t fit can lead to dead volume, which may cause pressure spikes, retention time issues and peak dispersions.

Using a guard column is also recommended to protect your column (depending on the nature of your samples) and increase the column lifetime overall.

We know ensuring the purity of your samples is crucial in chromatography.

To maintain this accuracy and precision, regularly cleaning your HPLC system will prevent contamination and lead to more reliable data, while keeping your equipment trouble-free for the maximum time.

Combining this with chromatography servicing will extend the life of your equipment and instruments, saving your laboratory time and money. Scheduled servicing and preventative maintenance (PM) help to spot problems before they become costly, decreasing the risk of lab downtime and reducing repair costs.

You can learn more about the importance of preventative maintenance in our blog, here.

The frequency of cleaning depends on how often you use your equipment, but it’s important to keep track on a rota to ensure it happens routinely.

As there are various ways to clean the system, depending on the analysis used, you should create a clean-down procedure for your chromatography laboratory.

We’ve placed an example of a basic universal clean-down procedure below.

The above are just a few helpful tips and good practices to help maintain your HPLC system, with our team on hand if there is something specific your system needs.

In order to further defend against poor chromatography, it’s also recommended to have a dedicated service plan.

At LC Services, we offer several service contracts that will help improve your equipment’s longevity and prevent future issues. We can even create a bespoke service, maintenance and support plan that covers all your laboratory analytical equipment, including operational qualifications and additional PM visits.

Each of our highly qualified engineers can deliver servicing for various brands and equipment, with our plans also including a 48-hour on-site response and phone support as standard.

Plus, if we spot anything which needs replacing, our reconditioned parts exchange programme can help you extend the lifetime of your equipment and has faster lead times.

LC Services are committed to customers, services and support for your chromatography analytical laboratory.

Our team and engineers support a wide array of machinery within numerous laboratories, servicing old and new equipment for various processes.

If you’re interested in learning more about our service plans and the models we support, visit our website here: https://www.lcservicesltd.co.uk/service-contracts/